Solvay, a leading global supplier of high-performance specialty polymers, reported today that Dacon Systems, an industry leader in manufacturing custom wire and cable, is increasingly specifying KetaSpire® KT-851 NT polyetheretherketone (PEEK) as an insulator for challenging wire and cable designs targeting downhole oil well and nuclear energy applications.

Solvay, a leading global supplier of high-performance specialty polymers, reported today that Dacon Systems, an industry leader in manufacturing custom wire and cable, is increasingly specifying KetaSpire® KT-851 NT polyetheretherketone (PEEK) as an insulator for challenging wire and cable designs targeting downhole oil well and nuclear energy applications.

“Downhole and nuclear environments present some of the harshest conditions in which our wire and cable products are installed, and these applications demand the highest performing materials,” said Mark Daniels, president of Dacon Systems. “Our customers are increasingly finding that KetaSpire® PEEK delivers unmatched durability and they are making it their material of choice for new applications within these industries.”

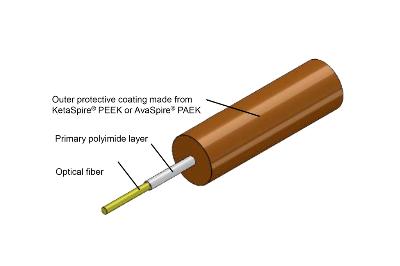

Typical wireline applications used in oil and gas down-hole environments transmit data for the purposes of well intervention, data logging and reservoir evaluation, and they are often subjected to extreme temperatures and pressures. KetaSpire® PEEK coatings are uniquely capable of meeting the performance demands of these applications and can enable cables to operate reliably in harsh environments. Specifically, KetaSpire® KT-851 NT PEEK offers reliable long-term insulation performance up to 240°C (464°F) with improved abrasion resistance vs. incumbent materials.

Solvay’s KetaSpire® PEEK also resists up to 1,000 kGy (100,000,000 rd) of gamma radiation, which can cause conventional fluoropolymers like polytetrafluoroethylene (PTFE) and fluorinated ethylene propylene (FEP) to become brittle. As a consequence, KetaSpire® PEEK is also becoming Dacon Systems’ first choice for coating wires and cables that transmit power or sensor data in nuclear plants. KetaSpire® PEEK polymers are inherently flame retardant and bromine- and chlorine-free. They also offer excellent low smoke properties. Cables insulated with KetaSpire® PEEK are being developed to meet the nuclear industry’s proposed 60-year lifetime rating, as well as the design criteria for cable function during Loss of Coolant Accident (LOCA) operations.

“Solvay offers an unmatched range of advanced polymers for wire and cable coating applications targeting electric power, data communication, rail transit, aircraft, shipbuilding and other industries,” said Glenn Cupta, business development manager for Industrial & Environment at Solvay Specialty Polymers. “KetaSpire® PEEK delivers the optimal mix of properties to meet the most difficult challenges when developing cable insulation for these very demanding oil well and nuclear environments. Our experience with wire and cable applications can further help identify the right product for specific applications, and provide the expertise and design support to minimize cost and increase yield.”

Among the highest-performing materials in Solvay’s unrivalled selection of specialty polymers, KetaSpire® PEEK imparts superior resistance to fatigue, stress cracking and abrasion along with excellent strength and toughness to wire and cable coating applications. It also has excellent melt strength and can be extruded into very thin 0.025-mm (0.001-in) coatings. Dacon can custom manufacture KetaSpire® PEEK wire in American wire gauge (AWG) diameters ranging from AWG 40 to 8 (0.08 to 3.3 mm).