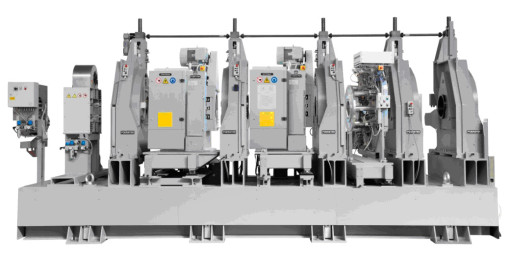

The German Group FOERSTER has been chosen as partner for the realization of a factory taking up 150,000 square metres for the production of cold rolled tubes without welding with different finishing lines and an estimated productive capacity of about 300,000 tons of steel tubes, which will be constructed in Shreveport, in Louisiana. For the second implementation phase of the project, amounting to 975 million dollars, they have provided for the completion of a foundry that will employ 675 people. FOERSTER company that develops, produces and distributes all over the world instruments for the non-destructive control of metal materials, for the detection of the material properties or of metals, for several years has been partner of Benteler GmbH, leader company of this project. To grant the highest qualitative standards that Benteler will produce in America for the first time, the company has ordered high-level technological plants for the testing of hot-rolled tubes to the German producer of non-destructive test systems for semi-finished products. Not only FOERSTER will supply the whole technology, including a CIRCOSON WT, but it will provide the entire mechanics with tables, drivers and automation. Besides, it will take care of the software integration of all instruments into Benteler finishing lines. In Shreveport, Benteler will produce tubes for the generation of energy, oil and gas, as well as for the chemical and petrochemical industry. In these fields, the properties of materials must be impeccable and granted by regulations like API and ASTM. The units will be delivered in 2015.

The German Group FOERSTER has been chosen as partner for the realization of a factory taking up 150,000 square metres for the production of cold rolled tubes without welding with different finishing lines and an estimated productive capacity of about 300,000 tons of steel tubes, which will be constructed in Shreveport, in Louisiana. For the second implementation phase of the project, amounting to 975 million dollars, they have provided for the completion of a foundry that will employ 675 people. FOERSTER company that develops, produces and distributes all over the world instruments for the non-destructive control of metal materials, for the detection of the material properties or of metals, for several years has been partner of Benteler GmbH, leader company of this project. To grant the highest qualitative standards that Benteler will produce in America for the first time, the company has ordered high-level technological plants for the testing of hot-rolled tubes to the German producer of non-destructive test systems for semi-finished products. Not only FOERSTER will supply the whole technology, including a CIRCOSON WT, but it will provide the entire mechanics with tables, drivers and automation. Besides, it will take care of the software integration of all instruments into Benteler finishing lines. In Shreveport, Benteler will produce tubes for the generation of energy, oil and gas, as well as for the chemical and petrochemical industry. In these fields, the properties of materials must be impeccable and granted by regulations like API and ASTM. The units will be delivered in 2015.

Wire Tech World © 2025 All Rights Reserved