A reality working with equal attention and competence at the manufacturing of new plants s well as at the overhaul of second-hand installations, with exemplary results in terms of product and service thanks to commitment, correctness and willingness. Diego Pagliarello, technical manager of Trafco, talks about that with us in this interview

From your point of view, how do you see the activity of the wire and cable production sector in the last period and what evolutions would you dare to hypothesize?

We express our opinion about the markets in which we are present: in this ambit, generally speaking, we do not perceive any change by wire and cable producers, unless the search for overhauled second-hand plants instead of the purchase of new ones, whose cost in Europe would be much higher that in Eastern Countries. Concerning this issue, we do not comment the eastern quality, because it would be banal. The phenomenon of the availability of worn-out second hand plants is evolving, in Italy and in other European Countries, and it is therefore interesting for us to analyse thoroughly customers’ possible needs of not extremely high productivity.

How can your company provide the right answers to the needs currently more highlighted by your customers?

Flexibility and willingness in solving production problems, the attention paid to the different requirements, the presence of technicians working at customers’ factories, also for a period of one or two years, in order to optimize the dynamics linked with the startup of a plant, or even of the whole factory: these, in short, are the answers that Trafco offers to customers’ and market’s requirements. Thanks to our President, Mr Franco Loturco, and to the relationships that he has personally consolidated in the past, still today we enjoy benefits in terms of continuity and fidelization of customers.

What relevance has the Research&Development activity for a reality that today intends to compete on the global market? How do you operate in this sense?

The Research & Development activity holds extreme importance. Unfortunately, however, it is not new that in Italy costs are high if the State does not pay the due attention. If our company was headquartered in Switzerland or in another North Europe Country, where you perceive higher legality culture and where resources are not wasted, today we would have already obtained more funds, necessary to develop and to accomplish the projects at which we are working without particular hindrances. Nevertheless, thanks to our sound and competent structure, we can prosecute the relative studies inside our company. Concerning this, training should be based on the reliable and concrete business practice, as it happens in the majority of virtuous Countries. Unfortunately, we have on the contrary to struggle with the hindering dynamics to which I have previously referred.

Among the various foreign markets with which you are in contact, what are the most dynamic and interesting ones in this period? And, about this matter, what percentage weight has export for your company?

We export over 90% of our production. Middle East and Africa have been for some time the most relevant markets for our company but we have anyway a strong presence also in Russia and in Belarus. Latin America, besides, is a historical market that we are recently integrating. Today export data should raise more the awareness of the system: we are astonished, in fact, by the scarce attention paid still today to this issue, despite the vital needs in outstanding matters such as the concessions on discount interests for international credits, the bureaucratic simplifications connected with export, the training linked with international trade, the limits of SACE and of the bank system and so on. We hope that the European Union sooner or later will unify the customs regulations of member States. Despite all current troubles, anyway, we still go on standing out for quality, courage and will.

In what terms do your machines and your lines share in enhancing the productivity, and then the competitiveness of the companies using them?

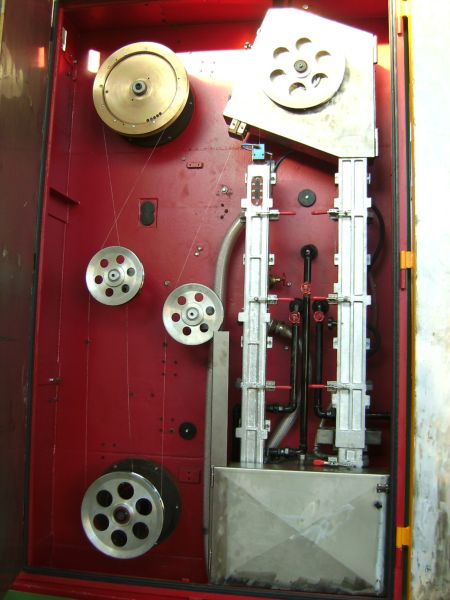

We supply new plants that show technical characteristics purposely studied according to customers’ specific needs. We have not, in fact, a “mass” production. Concerning second-hand plants, we equip all the lines that we overhaul with the most upgraded control and safety systems. Moreover, our plants grant really low consumptions and expenses. All that, as logic consequence, makes user companies more productive and competitive.

How have you gained your customers’ confidence? How do you make them feel your proximity?

Franco Loturco, president and founder of the company, has fulfilled an activity of fundamental importance in this matter. Thanks to the flexibility that characterizes our company and to the promptness in satisfying whatever service demand, we have provided continuous certainties to our customers. Commitment, correctness and good will have led to the excellent results that we have achieved, in terms of product and service.

What importance do energy saving and efficiency hold in the context of today’s industrial dynamics? What is the position of your company about that?

Energy saving and efficiency are undoubtedly crucial factors in the context of the current industrial dynamics, considering the high energy costs. Concerning us, the attention paid by our company to consumptions sees us on one hand committed to the design phase of a photovoltaic plant while, in the ambit of produced plants, we are increasingly oriented to the energy saving that they can offer.

Virtuous behaviours protecting the environment as distinguishing factors and competitive opportunities for today’s companies. What is your opinion about that?

Concerning the attention to the environment, unfortunately the sector in which we operate does not offer great opportunities of concrete expressions, yet. At present, in particular, we are proposing some plants for the recovery of the raw materials contained in machining rejects, consisting of lengths of electrical cable. Customers have showed great attention to that proposal, especially in foreign Countries with adverse socio-political situations, where economic dynamics always bring the attention to recovery with them.

All-round products and services

Trafco specifically stands out in the market context where it operates with its broad and diversified offer of lines and machines, able to cover the whole range of plants for the protection of whatever electrical cable, excluding optical fibre. The company in fact designs and produces: drawing lines for wire rod with capillary diameter for non-ferrous and precious metals, extrusion lines, stranders, single and double twist stranding machines, drum twisters, coiling lines, spooling systems, accessories. «In such diversified context, in this period particularly stand out – went on Mr Pagliarello – drum twister lines, with rotary decoilers up to 4 metres and 40 tons, and multi-wire drawing lines, very compact and fast ».

Besides, they supply services of engineering and know-how, training and management, technical-economical feasibility studies, besides complete turn-key factories. Inside a new line, if the customer is interested in it, Trafco can also integrate overhauled components, in order to knock down costs while at the same time granting production quality and competitiveness. The flexibility and the versatility that characterize the company lead it to acknowledge and satisfy whatever type of customers’ need.

Highlights on second-hand overhauled systems

As Mr Pagliarello underlined, today the consistent search for second-hand plants is particularly relevant, in line with the evolving availability of worn-out plants, in our Country and in other European nations. In that market panorama Trafco stands out not only for the design and manufacturing of new plants but also for its specialization in the overhaul of second-hand installations. «Recently – explains Diego Pagliarello – we receive also plants owned by the customer, which chooses the recovery policy and entrust us with the overhaul. With a second-hand overhauled plant purchased by us, we obtain an interesting price, European quality and operation warranty equalling a new one. Plants are often revised and upgraded with competitive productions at low costs ».