Thanks to the European union’s SME financing program horizon 2020, Macchine Speciali has developed a highly efficient industrial process, integrated and optimized for the PTFE extrusion of various products.

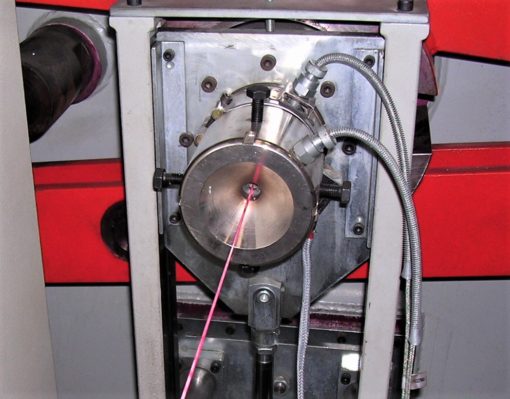

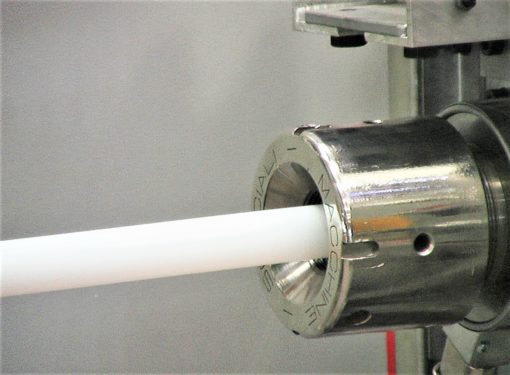

Established in 1996, Macchine Speciali designs and manufactures a wide range of equipment for cables and tubes. Thanks to the opportunity offered by Horizon 2020, a financing program for SMEs in the European Union the company has taken a new challenge. «Using our experience in machine manufacture for Solid or Stranded wire Insulated with PTFE extruded paste, – explains Dr. Giovanni Sironi, owner of Macchine Speciali – we can offer all the skills to improve your future production. With today’s PTFE powders availability, a wide range of draw ratios can be used and with controlling the preform charge size make production a much more efficient process. With the choice of larger diameter bore Ram extruders with long stroke capabilities a whole new range of options are possible for you the customer».

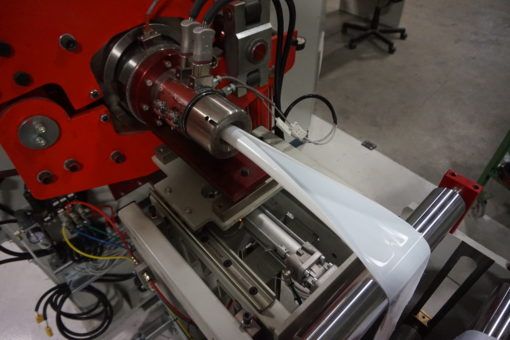

The ProPApp project (PROduction Process for high value APPlications) has led to the creation of equipment that includes all the necessary for the production cycle. This innovative system offers numerous advantages. First of all to be able to produce competitively P.T.F.E. expanded thanks to a better weight / volume ratio. «The technological solution adopted allows the production of a light version of P.T.F.E. tape, maintaining elevated thermal, electrical and mechanical properties. Reduce its density in favor of raw material saving up to 50%.».

ProPApp is an innovative industrial process, integrated and optimized for productions dedicated to market demands. «This means for the user – concludes Sironi – to increase its costs competitiveness and time for the extrusion. Another benefit is being able to produce an isotropic molecular structure that can withstand stresses without tearing». Skills and know-how, together with the opportunity offered by Horizon 2020, have allowed Macchine Speciali to develop equipment able to increase process efficiency, reduce energy consumption and maintenance costs, ensuring high performance of the final product with superior properties obtainable with a saving of raw material. A pilot equipment sheet / film demonstration plant is available at Macchine Speciali’s factory.

Company Brief Summary

Macchine Speciali began its experience as a manufacturing company in 1996, maturing its know-how and skills in the world of machineries for the construction of electric cables. With the contribution of a qualified team the company helps the customer in the selection and implementation of ad hoc machineries up to the achievement of the final product. The production is destined for national and international markets, ranging from unwinding and winding systems for any size reels, to single and double torsion stranding machines, taping heads, to special extrusion lines for PVC, Silicon and PTFE. Macchine Speciali also holds some patents, like the “Cordatrice Continua”, the “Coaxial Bivite” and the “Pulley with multiple degrees of freedom”, also known as “Free Pulley®”.