A company with a long tradition, standing out also for its capability of listening to and understanding customers’ requirements, with a philosophy centred on market demands. We talked about this reality, and several other issues, with Gabriella Kunz, president of O.M.D. Officina Meccanica Domaso.

How do you estimate the trend of the wire-working sector in the last period and what developments do you feel like to hypothesize?

The current market is particularly variegated and inconstant. In this period, actually, the majority of our customers show a notable growth trend but unluckily realities that are struggling to recover are not missing, too. This certainly depends on the markets that each company addresses, nevertheless what is highlighted is the total absence of that time warranty that allowed planning long-term orders. The current one is in fact a very limited perspective horizon, which goes almost overnight and then only permits a short-term planning.

What do you deem the suitable operational strategy for facing the challenges of a complex market like the current one? What actions does your company undertake in this context?

First of all, we must pay utmost attention to rising markets, which are those offering more opportunities. Today internationalization is almost a must, to a greater extent for Italian realities, due to the limited possibilities offered by our domestic market because of the political strategies adopted, which have induced several companies, even with outstanding brand and sizes, to escape. Concerning OMD, we are present on a world scale, with the export that constitutes 85% of our turnover, and we logically concentrate our resources in the markets that are presently giving us the greatest satisfactions: besides Germany and Europe in general, I am referring to Countries like India, Russia or China, but also USA, which are presently scoring a notable trade.

What are the requirements presently most expressed by your clients and how do you find the answers?

The philosophy that OMD pursues in its long tradition puts the market demands at the centre. The machines that we manufacture, in fact, have evolved over the years thanks to our capability of listening to, and understanding, customers’ needs, as well as to the technological innovation and the constant research of reliable high-quality components. It is just according to this value strategy that we satisfy, with the usual commitment, also the present market’s requirements, calling in particular for high flexibility, service, after sale service and, especially, a strong transfer of know how.

What relevance has the Research & Development activity today for a reality that intends to compete on the global market? How is your company organized in that ambit?

The Research & Development activity is very important, even better, it is essential. Because it is necessary to offer continuously innovative products, machines that are more and more performing and suitable for customers’ demands, to be able to solve their problems better and better. As far as we are concerned, we rely on an appropriate department where work several people, dedicated to the research and development of new products and new technologies. This activity is irremissible indeed, if we want to progress constantly, keeping pace with the needs and the requests of an ever-evolving market.

Energy saving and environment protection: which importance do they hold in the context of today’s industrial dynamics? What is your opinion about that?

The relevance of these factors is clearly considerable, in industrial ambit and not only and, concerning this, awareness is constantly rising. We equip, for instance, our machines with special state-of-the-art motors with very low energy consumptions, which allow adapting the kW consumption of the machine to its effective use. We have also undertaken some actions for the noise and powder emissions, always drastically reduced. They are then also solutions that protect machine operators and, therefore, workers’ health. Those issues are not new for us since we have always held in high esteem the point of view and the observations of operators, listening to their requests attentively, and not only to those submitted by companies, with logic positive repercussions and benefits for all.

How is currently composed your machine range and what essential features characterize it?

OMD produces grinding machines for springs, coilers, spring end grinding machines, twisting and bending machines to coil torsion or traction springs, lathes for cold or hot coiling, chamfering machines and cold and hot restriking devices, besides machines custom-made for each specific customer need. We offer advice and complete plants in Italy and abroad for the manufacturing and machining of springs, in particular valve, clutch and injector springs. They are about 60 the different types of machines that we currently implement, all conceived to achieve constant improvement: they are in fact increasingly automated machines and more and more based on the energy saving, the cost decrease and the absolute risk reduction, both for the operator and the machine itself. Concerning this, we have for instance provided also for self-diagnostics systems that protect the machine and its operation in case of wrong controls or movements by the operator.

In the ambit of your diversified offer, what are the outstanding machines and the latest novelties today?

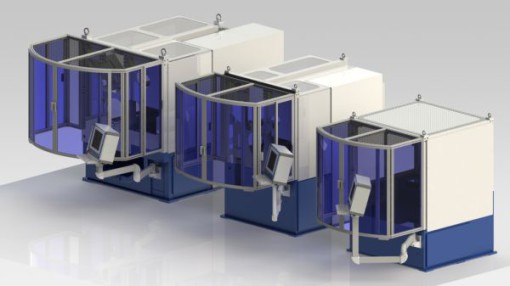

Considering the high technical and performance quality of our machines, which remains constant thanks to the continuous improvement applied to all models and to the different product families, I cannot state that there is an outstanding machine in comparison with the others. Nevertheless, it is worth highlighting here the multiformer TM3 and the new series of automated MA grinding machines. Conceived for the production of tension, torsion and spiral springs and round wire and/or square section bent components, multiformer TM3 is equipped with wire orientation system, universal double coiling head, universal electronic torque, transfer and double cut (linear and shears type). Besides, the use of the 22 CNC axes equipping this machine assures different technical possibilities for the production of any component type and an excellent flexibility in the changeover. The software is prearranged for the management of the double programme, to work simultaneously on the machining centre and on the second forming station. The machining cycle is simple and linear and the result is excellent, from the point of view of both the finished product quality and of productivity (5 pieces /min). The new automatic grinding machines series MA (with wheel diameters from 300 to 915 mm), with two vertical-axis opposite spindles, are instead dedicated to the simultaneous grinding of the two ends of compression springs and can operate in continuous or cycle modality, in the simple version or with double loading disk and double head. Several are the technological solutions adopted like, just to make an example, the development of special spindles for a better productive efficiency or the brushless motors for the management of all motions, while the new hardware components with EtherCAT type fieldbus permit a fast data transmission and, in case of connection in net, a remote online diagnosis. Besides, the programme structure and the graphic interface allow both a fast and simple running and an adequate answer to the growing needs of production management and quality and cost control.

What integrated products do you offer as completion of your machine range?

OMD proposes a complete array of integrated products, like furnaces, coilers, measuring and control instruments, automatisms, chamfering machines and so on, useful for the spring accomplishment: it is actually all that is related to their manufacturing, starting from the simple wire to arrive at the finished spring, including then heat treatments, pressing, chamfering and so on. We offer therefore also a complete range of products that add their performances to the already high capacities of the machines, making the work more streamlined and especially more complete.

In constant search of new solutions aimed at improving more and more customers’ operations, also this year OMD has presented two new patents. One of them is the innovative RLM system for the automated loading of loading disks by means of anthropomorphic robot, launched on the market on the occasion of the Wire 2014 exhibition. Main advantages of this new patented system are the high productivity and the reduced machine setup times. Loading times are drastically decreased thanks to the robot, which always stands above the loading disk and has the only task of depositing the springs inside holes; the load type can be chosen according to the grinding typology to be used. The plant, in general, is composed by a one-way spring selection/automation system and by an anthropomorphic robot on which is mounted the loading block. The latter is equipped by an equipment module, for a maximum of ten different diameters, which varies depending on the spring size characteristics and on customers’ needs. The operator must only choose the desired loading way for the spring to be automated because the set equipment, including the load sorter, remains always mounted, even if unused. Besides, keeping the external spring diameter unchanged, through a simple adjustment it is possible to load springs with different lengths. Another important peculiarity is that the system is integrated into the machine software, thus making the use simple and intuitive also for unexperienced users.

Professional ethics in the forefront

The target of OMD is the customer satisfaction, not only in terms of productive needs but also of service. In this way, they concretize a proximity to customers made of constant presence at their side, of immediate after sale service and solutions to problems. It is then established a confidence that springs from the traditional characteristic values of this company: competence, reliability, professionalism and certainly, last but not least, professional ethics. «It is also necessary to mention ethics in our work – affirms Gabriella Kunz -. When for instance we implement something reserved for a customer, we actually do that only for that company and we do not divulge it. Besides, this is also accomplished without anything in writing, but only on the word: a promise is a promise! Our customers know they can trust us and highly appreciate our ethical conduct, which has been characterizing us for 65 years».