For over 50 years it has been operating in the frontier of innovation in the manufacturing of drawing-dies for steels and non-ferrous metals. Today Van Dies, with the patented drawing-dies of the Adjustable Gold Series surpasses a new technological goal in the drawing of stainless steels for special applications.

For over 50 years it has been operating in the frontier of innovation in the manufacturing of drawing-dies for steels and non-ferrous metals. Today Van Dies, with the patented drawing-dies of the Adjustable Gold Series surpasses a new technological goal in the drawing of stainless steels for special applications.

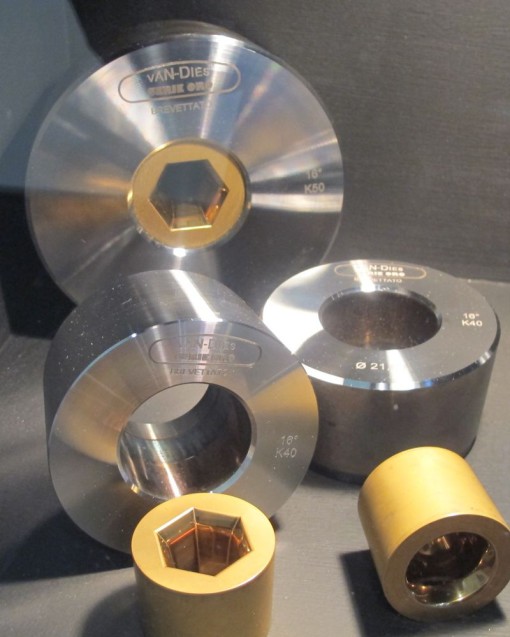

Adjustable Gold Series Drawing-dies.

The adjustable coupling, protected by patent, allows easily extracting the tungsten carbide core coated by CVD. The newly-born, protected by patent, is even made of gold. Not because the carbide has given way to the noble metal but due to the innovative design of the drawing-die. With the Adjustable Gold Series Drawing-dies, Van Dies at Arcellasco d’Erba (CO) surpassed a new target in the drawing of stainless steels of difficult machinability and of high-strength steels. The Gold Series drawing-dies summarize in fact the experience and the knowledge gained in over 50 years of activity by Albino Vanossi, founder of Van Dies and creative mind of the Research&Development team of this company that is unequalled in the high-end range of drawing-dies for steel bars and tubes and non-ferrous alloys, on the Italian and European market. The greatest innovation of the Gold Series consists in the possibility of comfortably extracting and reassembling the tungsten carbide core from the steel frame of the drawing-die, thanks to a coupling adjustable with micrometric precision to recover the demanded tolerance. This solution, protected by patent, enables the core coating with CVD before the final assembly of the drawing-die, thus obtaining a surface with very high resistance to wear. «The Gold Series was born from the boosts of our customers specialized in the drawing of stainless steels for special applications», explains Vanossi; «who demanded a solution to increase the drawing speed while keeping the same surface quality of the drawn part, then without having the possibility of executing the usual salting treatment of the rolled part. Only the CVD core coating can grant such performances, but the coating must occur before the final assembly, since the coating process at 1,050 °C damages the mechanical characteristics of the frame. The adjustable coating of the Gold Series exceeds this problem and, besides, the dismountable core can be coated and remounted several times, thus extending the service life of the drawing-die».