Communication between humans, machines and products – the fourth industrial revolution brings about demanding challenges.

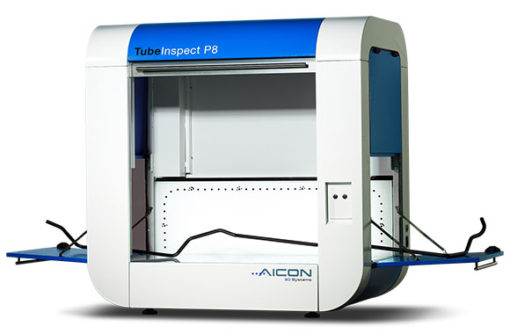

TubeInspect P8

TubeInspect, AICON’s tube and wire measuring system, already meets these requirements.

The measuring system may be directly linked to all renowned CNC bending machines.

If tube measurements indicate that adjustments need to be made to the tube manufacturing process, corrections are directly transmitted to the bending machine via the CNC program.

Günter Suilmann, Director Global Sales TubeInspect: “We are happy to provide our customers such future-oriented technologies. With TubeInspect and the software platform BendingStudio, AICON is well-prepared for Industry 4.0, because we efficiently connect different working areas and thus allow for a fast and reliable production process”.

TubeInspect P16

With TubeInspect P8 and P16, AICON responds to the constantly rising demand for tube measurement technology in manufacturing, e.g. the inspection of increasingly smaller tolerances.

The systems are equipped with latest camera and LED illumination technology as well as a highly precise and stable glass reference.

As a part of Hexagon, the aim of AICON is to combine technologies and ideas to enable close loop manufacturing.

Sensing, thinking, and acting – these are the terms AICON uses to define the way of integrated manufacturing processes with TubeInspect.