A new research branch with applicative perspectives to be fully discovered, a new frontier of “wire technologies” where, the consolidated textile knowledge is integrated with electronics, chemistry, biology and nanotechnologies.

A new research branch with applicative perspectives to be fully discovered, a new frontier of “wire technologies” where, the consolidated textile knowledge is integrated with electronics, chemistry, biology and nanotechnologies.

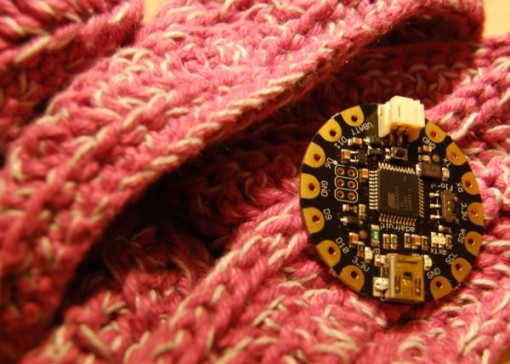

A textile, according to a general definition, is a manufactured good implemented by means of interwoven wires mutually perpendicular. The raw material is the so-called textile fibre, which can be natural, that is to say existing in nature, or of chemical origin. The first are of both vegetal and animal origin while the second, defined also techno-fibres are catalogued as follows: artificial, if produced from organic polymers existing in nature, like cellulose (rayon, viscose); synthetic, if produced from synthetic polymers (acrylic, polyester); inorganic, if produced from minerals or inorganic substances, that is to say carbon-free (metal wires, carbon fibres, fiberglass). In this context, at a certain time, a new category was added, called e-textile (electrotextile), evolution of the concept of Wearable Electronics, definition then turned, with what is considered the second generation of the wearable technology, into Wearable Computing, with some textile companies that started implementing products that allowed wearing hybrid type electronics. We must anyway distinguish the two technological branches opportunely: in the wearable case, electronics is an add-on, in the electrotextile it is integrated into the yarn. We can guess that when we talk about integration, sophistication levels are unlimited, and just to fix some reference points, scholars started referring to third generation of wearable electronics when the electronic function, and the more properly aesthetic one, of clothing began to hold the same importance, hence the complete merge between wearable and e-textile. However, this somewhat academic preliminary assumption does not fully coincide with reality since the three mentioned generations are not the classic shift from old to new, with the old that is given up, but instead a coexistence of applications and this is mainly motivated by the exponential growth of consumer electronics, to the extent that we are always searching for new use modalities, for instance wearing it.

A further conceptual complication derived from the diffusion of the “smart textile” denomination, expressed also as “smart clothing” and “smart fabrics”, which has superseded the electronic textile, probably more austere and less intriguing definition. In practical terms, we can state that a neat division between wearable computing and smart textile is currently accepted, context, the latter, where they emphasize the seamless integration between textile and electronic elements, typically microcontrollers, sensors, actuators, also bearing in mind that a smart textile must not be mandatorily wearable, as taught by several new concepts of the interior design. Besides, it is worth underlining that the great applicative possibilities of the smart textile have given birth to a specific technical-scientific discipline, the fibertronics, aimed at exploring how to integrate at best electronic and information processing functions into textile fibres. The recent technological evolutions have then led to identify two main categories of what we mean as smart textiles: those in which typical electronic devices like conductors, integrated circuits and also batteries, are embedded in clothes, and those with an electronics directly integrated into the textile substrate, and here we refer both to passive elements, like resistors and conductors, and to active elements, then transistors, diodes and solar cells, too. Despite all the comments here expressed, a certain sense of uncertainty on the real meaning of smart textiles remains, also because we have not faced the central issue, yet, that is to say their goal: why are they considered important and to do what? Starting from the purposes and from the results that, once reached, can give applicative and commercial value to textiles, it is possible to reach a quite significant “practical” definition: materials and structures able to perceive, and to react to, environmental conditions to be meant as mechanical, thermal, chemical, electrical and magnetic sources. Then, these reactions generate various functions like, for instance, those of Smart Socks, already presented in the 2013 September issue of Wire Technologies, where a whole range of sensors integrated into the textile measure the parameters concerning how the contact of the foot with the soil takes place, with a data collection by a specific anklet, actually an electronic device that provides for transferring data to a smarphone for visualization through specific application.

The smart textile market

Actually, instead of market prospects, in this part of the article we are highlighting what are the protagonist players, provided the obvious consideration that developing a smart textile requires an interdisciplinary approach, leading to more strictly market consequences, like products and their diffusion. The essential point is that textile, electronics and software industries have fully different productive cycles, industrial cultures and price policies. Then, the current technology supports only “special-purpose” products in low volumes and, for a mass production, we need a neat separation between the textile production and what we have previously defined the capability of perceiving, and reacting to, environmental stimuli, transferring the entire complexity to electronics and software. This approach leads to the concept of “wearable sensing” as app, term today widely diffused to indicate computer applications dedicated to devices of mobile type like smartphones and tablets. The central problem is represented by the fact that there is not a killer app for smart textiles, yet, in other words a totally winning application enabling the production of big quantities of identical garments, obviously from the sensing capacity point of view; there are instead several different apps with different sensing requirements. To reach those mass productions needed for a turning point of the smart textile market, research is pursuing a level of abstraction permitting to replicate for the textile sensing what already done with smartphones and related accessories for the context of mobile devices. In the early days of mobile computing, general purpose platforms were not available and to create a new sensing app they had to develop new hardware and software, with high consequent costs and unavoidable niche diffusion. However, the advent of state-of-the-art smartphones with diversified sensing functions has then allowed creating mobile applications not depending on a specific context since they can be hosted by the “smartphone” platform, hence the boom of the app market, which has further driven the smartphone one. Still talking about smart textiles, the research is then trying to implement low-cost textile structures, with electronics and capability of processing signals, from which to derive complex and useful information for users, from time to time structured as apps according to the functional purposes. Actually, they pursue a base smart textile platform, with sensing general purpose abilities to be afterwards specialized but also preserving properties of adaptability, wearability and comfort: otherwise, even if smart, it would not be a “textile” any longer.

The target of a textile that becomes part of a sensing device, since integral part of the functions of the device itself, imposes the development of textile fibres with forefront sensing and signal processing properties, to be directly integrated into standard fabrics with the manufacturing processes of the textile industry. Nevertheless, even if some research centres have developed techniques permitting to integrate transistors and sensors into what are nowadays called “wearable plastic fibers”, we have still to solve the whole of issues concerning the mutual interconnection among the various sensor fibers in the textile, and how to protect this part of sensitive fibres from bending, stretching and stresses that, while generally acceptable in a standard textile, it this case might cause damages. All that without forgetting that an energy source is necessary. All electronic devices, even if miniaturized and featuring very low consumption, must be power supplied and the integration into smart textiles of solutions allowing the self-powering is a very critical part of the research. Actually, the solution is already within reach accepting the use of adequately positioned batteries that must anyway be managed and removed in some determinate situations (it should be possible also to wash a smart textile). The other option, more consistent with the context of smart textiles, is represented by “flexible batteries”, and there are already some interesting solutions that unblock a situation that seemed in total stagnation. As a matter of fact, before the latest technological innovations focused on flexible batteries, rechargeable through integration with light and miniaturized solar cells, research had focused on piezoelectric nano-wires, from which to draw nanofibers generating electricity through motion, but the power per area unit was very low: the power supply of a standard AAA battery with lithium ions would have been obtained only from an area equivalent to a football field. Still speaking of flexible batteries, researchers of KAIST, Korean Advanced Institute of Science and Technology, have developed a very promising technology for what they have called “foldable batteries”. The approach is fully of not-conventional type, being based on a polyester yarn coated by nickel and polyurethane, to form all the basic elements of the battery, and with recharge supplied by flexible solar cells with sizes and physical characteristics allowing the “embedding” into clothes. It is worth noticing that the researchers’ goal, apart from smart textiles, was the wearable computing or anyway the possibility of powering state of the art consumer devices, like Google Glasses and smartwatches.

The role of nanotechnologies

The nanotechnology is a branch of science and technology applied to the material control and handling in sizes under the micrometre (µm, millionth of a metre), between 1 and 100 nanometres (nm, billionth of a meter), for the implementation of highly miniaturized devices. Nanotechnologies presuppose the capability of observing, measuring and handling the matter on atomic and molecular scale and at these levels the behaviours and the characteristics of the matter change, hence a radically new way of producing to obtain materials, structures and devices with improved, or fully new, properties and functions. In some scientific publications we can read that smart textiles are materials with sensors implemented through nano-technological elements able to measure significant data of a human body or of the surrounding environment (and here we go back to the wearable sensing). It results then that the smart textile issue belongs to the wider ambit of nanotechnology, especially concerning the processes adopted to obtain fibres with sensing capabilities. An emblematic case regards the transformation of the standard cotton into conductive wire by modifying it with carbon nanotubes (CNT, Carbon NanoTube). The process, drastically simplified in the various phases, starts from the repeated plunging of the cotton wire into what might be defined CNT solution, then letting that the natural fiber dries each time. After several immersions, they noticed that cotton becomes conductive, with a resistance of around 20 Ω/cm, suitable value for sensing applications. That effect is long-lasting, since the absorbed CNT is removed neither with the use of solvents and the material, which has become a “nanotube-cotton composite” for nano-technological process, fully maintains its original flexibility, then the possibility of traditional processing. Another method derived from nanotechnologies is the atomic deposition (ALD, Atomic layer Deposition), with which to make a special material layer grow on the surface of textile wires of different nature to obtain conductive fibres for textile processes. In this case experimentations make use of a compound called RGO (Reduced Graphene Oxide). As curious detail, witnessing the exasperate interdisciplinarity demanded by smart textiles, the latter technique provides for the use of an animal protein, the BSA, Bovine Serum Albumin, as molecular glue that improves the RGO absorption by any textile wire, both natural and artificial.

Not only smart textiles

Researches on new fibers are providing relevant results also in not necessarily homogeneous fields like the smart textile ambit, and an example is the first collection of luxury clothing for men produced in Canada by the dressmaking Garrison Bespoke. The peculiarity of these garments resides in the fabric, “bulletproof” granted, then an elegant, even if expensive alternative (20,000 dollars per dress) to the usual bulletproof kewlar vests. The textile is based on carbon nanotubes and is implemented through nanotechnology processes, in this case not aimed at making a conductive textile texture for applications of wearable sensing but at protecting with style.