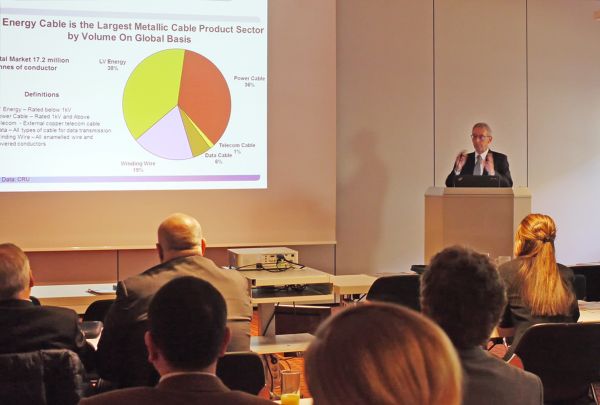

Some phases of CabWire World Conference, held in Düsseldorf, in Germany, last November.

Automation, user-friendliness and especially ecology: they are the main issues faced during the CabWire Conference held last November in Düsseldorf.

Vittorio Pesce

Last November it was held in Düsseldorf, in Germany, the seventh edition of the CabWire World Conference, the primary world meeting in the sector of ferrous and non-ferrous wires and cables. The event, even if not up to the previous edition, “hosted” by Milan city, in terms of organization and venue, has anyway aroused the interest of many sector technicians and experts come from all over the world.

During the meeting, they collected and analysed the proceedings by the various international associations (CET, WAI, IWMA, IWCEA, and ACIMAF itself) and by the reference sector businesses, which have presented technical speeches of great relevance.

The speakers, coming from Germany, United Kingdom, Switzerland, Canada, Belgium, India, as well as from Italy, illustrated subjects of technological character, anyway always concerning the current market context, which has allowed outlining the state of the art of the wire sector and reasoning about the prospects and the challenges awaiting us in the next years.

Italian speeches, presented by outstanding companies such as GCR Eurodraw S.r.l., Koner S.r.l., Samp S.p.A., Sicme Italia Impianti S.r.l., Continuus-Properzi S.p.A., were highly successful for the technical level and the innovation content.

We are hereafter reporting, necessarily in synthetic way, all speeches that followed one another in the course of CabWire Conference. Those who are interested in getting more specific information, can contact the secretary of ACIMAF to have a copy of them.

The forefront “non-ferrous”

The programme concerning non-ferrous materials started with two topics of general character: Klaus Probst from Leoni AG (Germany) proposed: “Success factors for sustainable international growth”; Robert Daniels, CRU Group (UK): “Recent developments in the global cable industry including the future outlook”; while Ralf Wallmeyer from Ideal-Werk (Germany) analysed technical aspects more in-depth, explaining and illustrating advantages and peculiarities of the so-called “dual force” welding in the ambit of non-ferrous wires.

Highly appreciated were the speeches by Enrico Conte from SAMP S.p.A, “Application of new technologies in the drawing of coated wire and subsequent insulation with high-temperature materials”; and the one by Stephan Gorgels, from Maschinenfabrik Niehoff GmbH (Germany), “Manufacturing solutions for alternative materials to copper for automotive wires”.

Holger Lieder from Sikora AG (Germany) explained to what extent “Highly pure XLPE material is essential for high-quality EHV and subsea cables”.

The day continued with the report by Sean Harrington, Ceeco Bartell Products (Canada): “Manufacturing of compact conductors, highlighting the benefits and potential costs reductions in the whole stranding process ”; and with the speech by Prajakta S Dhamorikar from C Tech Corporation (India): “Rodents not just a nuisance but a threat to the wire and cable industry”.

Of great relevance were then the speeches by Rupert Parmenter from SICME Italia Impianti S.r.l.: “Revolutionizing the wire manufacturing process”; and by Carmelo Brocato from Continuus Properzi S.p.A.: “Properzi adds continuous rotary extrusion to its range of equipment to provide an integrated solution for the production of ACSR/AS conductors”.

The programme ended with the speech by Albert Groothedde, from Innovites BV (Holland), “Making IT work in the wire and cable industry”, and the one by Horst Scheid, from SIEBE Engineering GmbH (Germany), “Foam insulation in cable extrusion – technology fundamentals and some case studies”.

“Ferrous” novelties

“Ferrous” novelties

Concerning the “ferrous programme”, Lorenzo Facchinelli from Eurodraw Wire Equipment S.r.l., presented “New electro galvanizing line with insoluble anodes technology”; as interesting was the theme treated by Andrew Stacey from Stonepark Consulting Ltd (UK): “Practical Use of Computer aided design for optimising Wire Rope Design and Manufacture”.

Stefan Freitag from “data M Sheet Metal Solutions” (Germany) stressed the software issue: “Design and simulation of rolled profile wires with modern CAE tools”; whereas Jörg Inhelder from FMS Force Measuring Systems AG (Switzerland) presented “Improved transmission of critical signals in bunchers, twisters, stranders through use of wireless systems”.

Sean Harrington from Ceeco Bartell (Canada) illustrated “The use of steel strip, shaped wire and round wire in the production of umbilical cable and submarine cable”; Walther Van Raemdonck from NV Bekaert SA (Belgium) highlighted instead “Heat resistant colour coatings for a new generation of spring wires”.

Great interest aroused then the “made in Italy” study presented by Fabio Bellina from Koner S.r.l.: “Technological progress in the drawing of zinc-coated wire by a new type of tungsten carbide dies”; as well as involving was the report by Guido Kellmann from TRAXIT International GmbH (Germany): “New efficiency of coatings and dry drawing lubricants”.

The “ferrous” programme ended with the speech by Rene Branders from FIB (Belgium), “New design in open fire furnaces”, and with two reports of German origin: “Energy-efficient drive system for winding machinery” by Juan Carlos Gonzales Villar from Kabel.Consult.Ing and “A holistic view of the in-line wire cleaning” by Peter Terliesner from GEO-Reinigungstechnik GmbH.

The academic contribution

De Montfort University (UK) presented three scientific studies. The first proposed a comparative analysis between two different analytical approaches: “Comparative study of two scheduling approaches to resolve scheduling problem for a wire and cable manufacturing process”; the second, “Enhancing the power and data capabilities of structured cabling”; the last one, “Unbalanced transmission channel model simulation for CAT7A Ethernet cable”.

Ferruccio Bellina, president of ACIMAF.

Convulsive global market

The participation in Düsseldorf convention allowed us to have a short dialogue with Ferruccio Bellina, president of ACIMAF, Italian Wire Machinery Manufacturers. «The meeting in Düsseldorf – started the president – aroused less enthusiasm than the previous Milanese edition, not only owing to the organization, certainly of lower level, but also in terms of attendance. Several managing directors of companies in fact deserted, maybe due to the proximity in time with Wire exhibition, which will be held in Düsseldorf in April 2016».

For that reason, precisely to avoid a certain “conflict” between the two events, the next edition of CabWire Conference, in 2017, will not be held in Germany, in Düsseldorf in particular. «Precisely. In spite of that, I do not want to diminish the importance of the event of last November, on the contrary, various speeches stood out for their high level and attracted the attention and the esteem of the participants. Besides, I am pleased to say that Italian speeches were among the most appreciated».

What are, in your opinion, the innovation “guidelines” emerged downstream CabWire Conference 2015? «The main development trends concern the environment protection, referring in particular to the reduction of energy consumptions and the decrease of noxious emissions, besides the improvement of human work conditions. This means to make machines more automated, ergonomic and user-friendly, with faster and more intuitive “user interfaces”,».

Does automating machines mean also reducing the “weight” of human intervention inside manufacturing processes? «Yes, certainly, also to deal with the shortage on the market of specialized manpower, skilful in operating on machine board. However, making the machine “automatable” means also innovating, and innovation is the only weapon that European manufacturers have to keep on being competitive. If we “fought” against Chine producers in terms of price, we would have immediately lost. Therefore, the only course consists in increasing the technology level of our products in terms of ecology, improving the user friendliness, ergonomics, automation; this is not simple, also owing to the scarce financial aids allocated by entrusted Bodies, at least in Italy ».

Referring to Far-East Countries, the opinion of Ferruccio Bellina is very clear: «Finally, also in those Countries the labour cost is rising, which means that the East-West gap is gradually decreasing. Not fortuitously, some companies start abandoning China in favour of Far East Countries where costs are still lower, such as Vietnam, even if it is early to speak of “new exodus”. Concerning China, it is worth noticing that not only it is living a phase of economic slowdown but it is also starting a “growth” phase in the issues of pollution, workers’ safety, protection etc. In other words, manufacturing costs will rise in China too, and sooner or later protectionist policies and the relevant incentives to export will finish, to full advantage of our enterprises».

Talking about technological aspects again, Bellina specifies: «One of European manufacturers’ challenges consists in releasing on the market not only “high-end” machines but also “entry level” models, that is to say machines with a good quality/price ratio and appealing for the buyers with not huge investment possibilities. In this way, customers will have the chance to choose».

What is, however, the health state of Italian enterprises? «Our companies – notices Ferruccio Bellina – are competing on equal terms, regarding the product quality, with German enterprises, which represent anyway our primary “rivals”. Nevertheless, there are great differences in the “Country-system”, and obviously to our detriment. The labour cost does not make the difference so much, since in Germany it is even higher than in Italy, but instead infrastructures, much less efficient by us. I mean that the “Germany-System” allows enterprises, on average of bigger size than ours and therefore “sounder” in themselves, to be supported by banks, by insurances, by local Bodies and so on; this produces a transversal synergy that Germans fully exploit and that we absolutely miss».

Is it possible that we have made no progresses in that ambit? «The situation has certainly improved, we should just consider the support that ICE, the National Institute for Foreign Trade, is trying to give us. However, the course is still very long. We should also say, however, that enterprises seem to be finally aware of the problem. They have understood that it is no more sufficient “to get by”, but it is really necessary “to teamwork”, “to group together” and to look for synergies among enterprises».

Is it possible that we have made no progresses in that ambit? «The situation has certainly improved, we should just consider the support that ICE, the National Institute for Foreign Trade, is trying to give us. However, the course is still very long. We should also say, however, that enterprises seem to be finally aware of the problem. They have understood that it is no more sufficient “to get by”, but it is really necessary “to teamwork”, “to group together” and to look for synergies among enterprises».

Another of the worst “evils” of Italy is today, still today, bureaucracy. Bellina: «According to my personal experience, as entrepreneur, I can affirm that bureaucracy in Italy is still deadly. It frightens our enterprises and, even more, it scares foreign ones that try to invest by us. The system of authorizations, preliminary approvals, advices, of asseverations by professionals, of delays and so on is a real wall that discourages and, even more, contrasts investments. Time losses are enormous, the energies consumed excessive and the costs to be borne, even before making investments, really exaggerate. We have been trying for years to solve the bureaucracy problem in Italy but it is really a hard nut to fight».

To end, Bellina analyses a wide-ranging topic, that is to say how the difficult economic and political international conditions are affecting the wire industry: «Our sector mainly grows thanks to major works and infrastructures, linked for instance with the energy ambit, of big constructions and so on. Unfortunately, the “global” situation is not rosy at all: wars, economic sanctions, “Arab springs”, tensions, etc., have stopped several of these works, actually hindering the investments of several Countries. It is worth considering, for instance, Russia, which is terribly suffering owing to the economic sanctions imposed by western nations, which have substantially stopped the industrial growth process started by Moscow over the last few years. At the same time, western businesses, Italian ones first of all, which had invested a lot in the Russian market, are even more damaged. Not only Russia, however, causes concern: China, as said, is slowing down, Brazil is actually stagnant and in Italy nothing lets us foresee that in the next few months we will live a substantial market recovery, at least in our sector. In other words, the whole world situation is a reason of concern, with the exception, perhaps, of United States that, despite all, never stop growing».

Bellina ends in any case looking at the future with optimism: «Optimism must be in the DNA of each entrepreneur because only with the hope of growing and widening the market, it is possible to invest and “to risk”. For this reason, we must be confident and believe that things, we hope soon, will improve».